Frank - first phase -modeling in Plasteline

for cold cast bronze. This is my dad so I'm making several

copies as Christmas gifts for the family.

|

|

|

Side and front of finished model.

The surface can be smoothed with a paintbrush and sponge dipped

in mineral spirits. Then the head is sprayed with shellac to

seal it in preparation for the mold making.

|

|

|

Making the mold - 2nd layer of silicone rubber has just

been applied on this 2 piece mold (left). One more thick layer

to go, then the clay barrier (divider) is removed and rubber

mold is made on the other side (right). I am testing some

new mold material - the pink is Smooth-On's Mold Max shore

20 and the yellow is Mold Max shore 10. Both of them turned

out to be too runny for vertical application (even when used

with a thickening agent), so I now use Mold Max shore 30 (which

is blue) for all of my molds. It has the perfect consistency

and is very strong.

|

|

|

When cured, the supporting shell mold is made over the top

of the rubber mold (left). This is a fiberglass resin - light

and strong (smooth on "Plasti-Paste") . The shell

mold is made in three sections to make sure it will come off

easily - one section for the back and two sections for the

front. The next day, the mold set can be removed and is ready

for castings (right).

|

|

|

Mold assembled and poured. Rubberbands hold

the mold together around the knobs created for that purpose

(left).

For additional support, tie the mold tightly with non-stretching

rope or sections of bicycle tire intertube straps tied

securely around the mold. A mixture of 90% bronze powder with

10% binder and a touch of black pigment is poured in the bottom

opening and rolled around to coat the top 1/4 inch layer of the

piece. When the bronze layer has set up, the head is filled with

polyurethane resin. The pour takes 2 minutes to harden

and can be unmolded in an hour (right). |

|

|

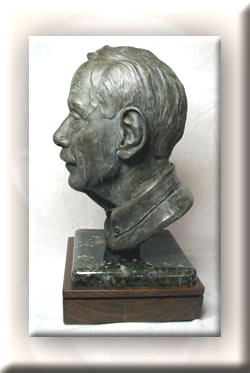

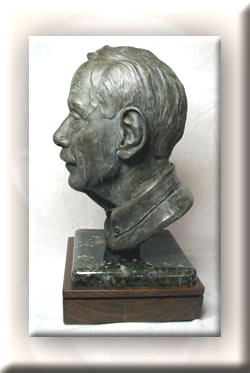

Next,

I used Tiffany green acid patina to give the piece some added

depth and color (left).

Buffed

with a dremmel tool, waxed with a layer of warm brown wax and

buffed, the piece is now ready for mounting on its base (below).

|

|