|

|

To make the mold, I start out with a strip of

clay rolled out long and flat. With this small mold, I'll make

the rubber mold as one piece with a seam up the back and will

make the rigid mold in two pieces. That way, there is no seam

running down the center of the face to deal with. Place the

strip of clay along your dividing line. Plug any holes that

will need to separate so the mold can be removed - such as

between the neck and pony tail. With the eraser of a pencil,

I pushed keys into the clay that will later serve to lock the

two halves together and keep them from slipping. Spray the

entire thing with mold release and brush it in all cracks and

crevices with a small paintbrush.

|

|

|

I am using Polytek's polygel 40

which is a simple to use, 2 part urethane rubber. Mix a small

batch of equal amounts and brush over 2/3 of the sculpture.

Use the brush to push the rubber into all tiny areas such as

up the nose, corners of eyes and mouth, etc., so no air bubbles

get trapped there. The rubber sets up in about 5 minutes and

a second coat can be applied when tacky in about an hour. Build

the ridge thicker than the rest.

|

|

|

The next day, remove the clay divider from the seam and plugged

holes. Spray the back side of ONLY the seam with a silicone

based mold release, and also the backs of the plug holes so

the rubber doesn't stick to itself. Take care not to get any

release on the rubber that is painted on the face or new layers

won't stick. You can cover the rubber on the face temporarily

while you spray the seam. Paint two layers of rubber on the

exposed side.

|

|

|

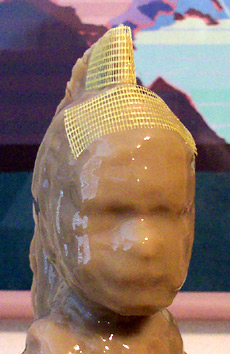

When tacky, paint another coat of rubber over the whole thing

and fill up any undercuts that the rigid mold might catch on.

I cut a piece of fiberglass tape and placed it at the edge

of the seam for reinforcement. Paint one last layer of rubber

over the entire piece, including over the tape.

|

|

|

The next day when the rubber has cured completely,

cut about 1/8 inch of rubber from the outer edge of the seam

to make a nice clean separator line. Place a strip of clay

down the front half of the mold, and press keys. Spray

one half of rubber mold with mold release in preparation for

making the rigid mold.

|

|

Quickly mix plaster of paris with water to

the consistency of cake frosting. Too thin, it will run off

- too thick it will set up too quickly and start to crumble.

Apply a thick layer with a spatula on the half of the sculpture

you sprayed with release. You have about 10 minutes of working

time before the plaster is too stiff to work. Wait an hour

and apply a second layer, building the plaster thick at the

edges. Plaster is messy and best done in the shop or garage.

Here I laid the piece on a pillow covered with plastic.

Sorry about the white on white photo.

|

When the plaster is dry, the next day, remove the clay strip

and spray mold release on the other side. Apply Dawn or Polmolive

dishwashing liquid on the exposed plaster to act as a barrier

between the two sides. Let dry for 10 minutes and mix another

batch of thick plaster to make the back side of the mold. Apply

two layers.

|

|

|

|

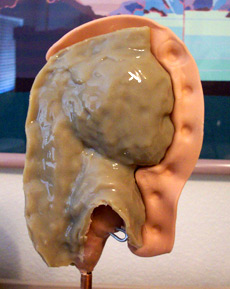

When the plaster dries, the piece can be un-molded. Find an

edge, stick in a screwdriver and slowly twist. Should pop right

open. |

Pull the rubber mold open at the seam. The original piece

should pop right out, undamaged. Wash the rubber with soap

and water.

|

|

Here is the final mold. It should always be kept assembled

and strapped with rubber bands to prevent distortion. The mold

is now ready for the wax investment stage. |

Hard casting wax is melted and poured into

the mold and rolled around. This process is repeated several

times until the layers of wax are built up to an even thickness

of about 1/8 inch. The hollow wax bust is taken out

of the mold the next day when totally cooled and any seam

lines,

bubbles, and flaws are re-sculpted with wood carving and

other wax working tools.

|

|

|

As a side note, once you have a mold, you can cast just about

any material in it including wax (for bronze), resins, slips,

porcelain, and more.

Here is a quick cold-casting in bonded copper as a less expensive

alternative to lost wax castings. The copper will react with

an acid patina because there is real metal powder in the

mix. Left - just out of the mold. Below - with a white patina

applied.

|

|