|

|

This demonstration will cover making a polymer

miniature bust from concept to finished piece in lost wax bronze.

To start, I study the reference photos and make several

of these quick computer mock ups to visualize the pose, expression,

hair treatment, and technical aspect of how to build the sculpture.

|

|

|

Left - Next, I print off

a photo to scale of a good profile shot. I drill a hole in

a board to hold a 12 inch piece of copper pipe. The pipe needs

to be able to be moved in and out of the hole easily. For a

miniature, most of the time I will hold the pipe in one hand

and sculpt with the other. This allows me to turn the sculpture

in all directions and view all angles while sculpting. Also,

I do not squish the soft clay with my left hand by holding

it directly.

Using one continuous piece of 4 gauge aluminum

wire, I slide the wire all the way down the tube and bend the

upper portion with pliers to form a structure that fits well

within the interior of the scaled image.

Right - I place a small ball of aluminum

foil in the interior of the head mass (brains) and then cover

most of the armature with polymer clay (super sculpey), down

past the top of the copper tube. I bake this portion for 20

minutes at 200 degrees to harden. This makes a firm, sturdy

armature on which I can add the soft clay. |

Next, the clay needs to be conditioned. Chop up 8 oz

of Premo Sculpey (hard) and 8 oz of Super Sculpey (soft). Mix

and gather the pile into a ball, then roll out into a long

rope with the palms of your hands. Fold the rope over itself

and repeat rolling to a rope. Repeat 5 or 6 times to mix and

condition the clays well. This makes a medium consistency clay

that won't crack or crumble. |

|

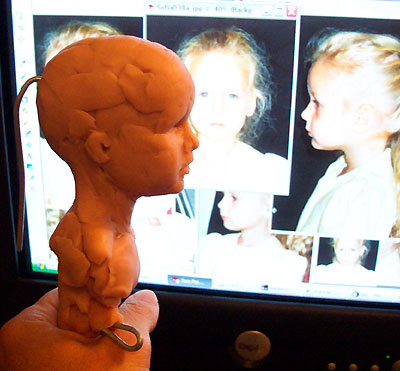

Above is a quick rough-in of the basic head shape/volumes.

I like to work from my computer screen whenever possible -

the images can be seen more clearly than if I were to print

them off, plus, I can zoom into any portion for a sharp view.

|

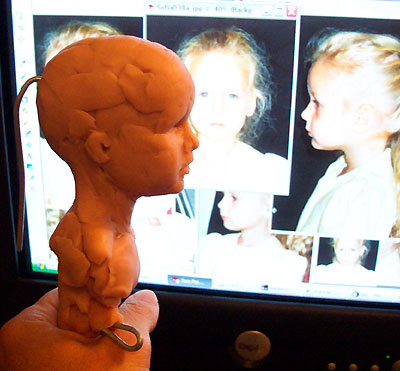

A little farther along, part of the hair, ears, and upper

body are roughed in. After the rough in is complete, I'll study

the photos and adjust/refine the sculpture to work on getting

a close likeness.

|

Another day of modeling passes. At this point, pieces of clay,

no bigger than a pinhead are carefully applied with a tiny

flat dental tool and smoothed into the surface. The ear

was modeled with a flat toothpick and an embossing tool.

|

|

I decided to go ahead and start adding her dress and pony

tail at this point. Since she is wearing a delicate little

flower

pattern dress, I thought it would be fun to make some little

flower stamps to use for the texture. I carved some tiny flowers

and cut a circle around these and baked them. This made a nice

hard stamp head that I glued on to a chop stick and imprinted

the clay used for the dress. I ended up using only the small

stamps - the others looked too big on that small space. |

|

Here she is with her little flower dress - though hard to

make out in this photo. Pony tail added also. If you don't

bake the

clay until the piece is completely finished, you can rework

any portion at any time. I pretty much reworked the entire

face to

try to get a better likeness.

|

Now it's time to put it under the bright lights, put on the

magnifier glasses and start the refinement process. The clay

can be smoothed and blended with a very small brush dipped

in lighter fluid (use sparingly).

|

After looking at these photos, I decided she

wasn't quite finished modeling. I proceeded to make her pony

tail a

bit longer and fixed the scalp portion of her hair which had

somehow ended up resembling a cantaloupe. Finally, I declared

her finished. I then placed her on a bat of polyfiber and baked

her at 200 degrees for 2 hours. That's what is great about

this clay - no special equipment needed to harden it.

After baking the clay, let it sit in the oven

and cool down completely overnight. If you take it out while

it is still warm, there's a good chance it will crack. |

|

After the piece is baked and cooled, you can polish it up with

steel wool. You can also use fine wet/dry sandpaper (use it wet)

to smooth out any rough areas.

Rinse the piece well with water, or use a can of air to blow

off all particles. Wipe well with a soft, dry rag. The piece

is now ready for the next step - molding. |

Final version in Polymer clay

|

|